Thermal Imaging

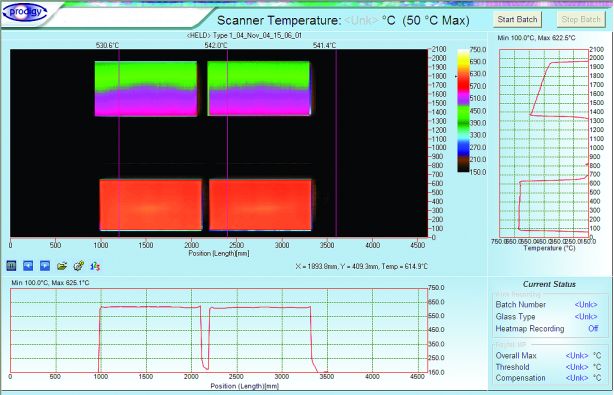

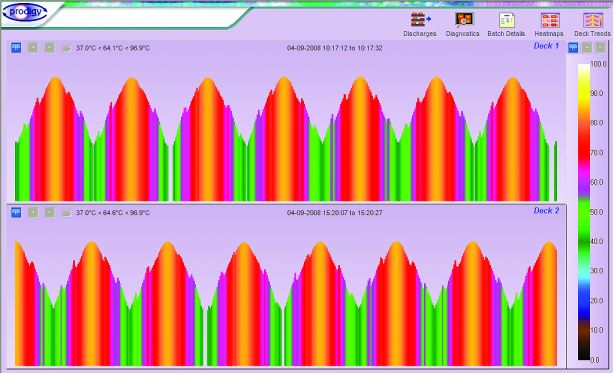

Prodigy provides complete support for real-time thermal imaging for continuous or discrete processes.

It can capture, display, record and analyse information from multiple thermal line scanners to provide live thermal images, production records, alarm monitoring, real time analysis of production quality and early warning of manufacturing problems.

Whilst the core thermal imaging tools can be applied to any thermal process a range of Industry specific configurations hay, been specially developed to provide ‘out of the box’ solutions for most of the common applications.

Display Types

Prodigy provides a number of ways to view thermal data including real time, full colour thermal images, Thermographs, 3D waterfall display and sector trends.

|

|

Data Recording

Data can be captured for long term storage based upon a range of continuous or batch based options. Scans can automatically include pre and post-trigger information based upon time or number of scan lines. Prodigy can maintain a rolling buffer of captured data, automatically deleting the oldest data to me up storage space and retaining key records for long term storage as required.

Automatic Data Analysis

Each scan can be analysed to check for manufacturing problems This can include max, min & average temperatures, product surface area, part count, emissivity correction, hot/cold spots etc.

Fully Integrated Solution

Unlike the simple software packages provided by equipment manufacturers, Prodigy is able to provide a fully integrated system. It can connect directly to your existing control and monitoring equipment to provide a range of capabilities which cannot be achieved using a stand alone package. This is why many original equipment manufacturers have chosen Prodigy as the basis for their own systems.