Prodigy IBC Tracking System

Delivering Results, Right Down to the Last Drop of Oil

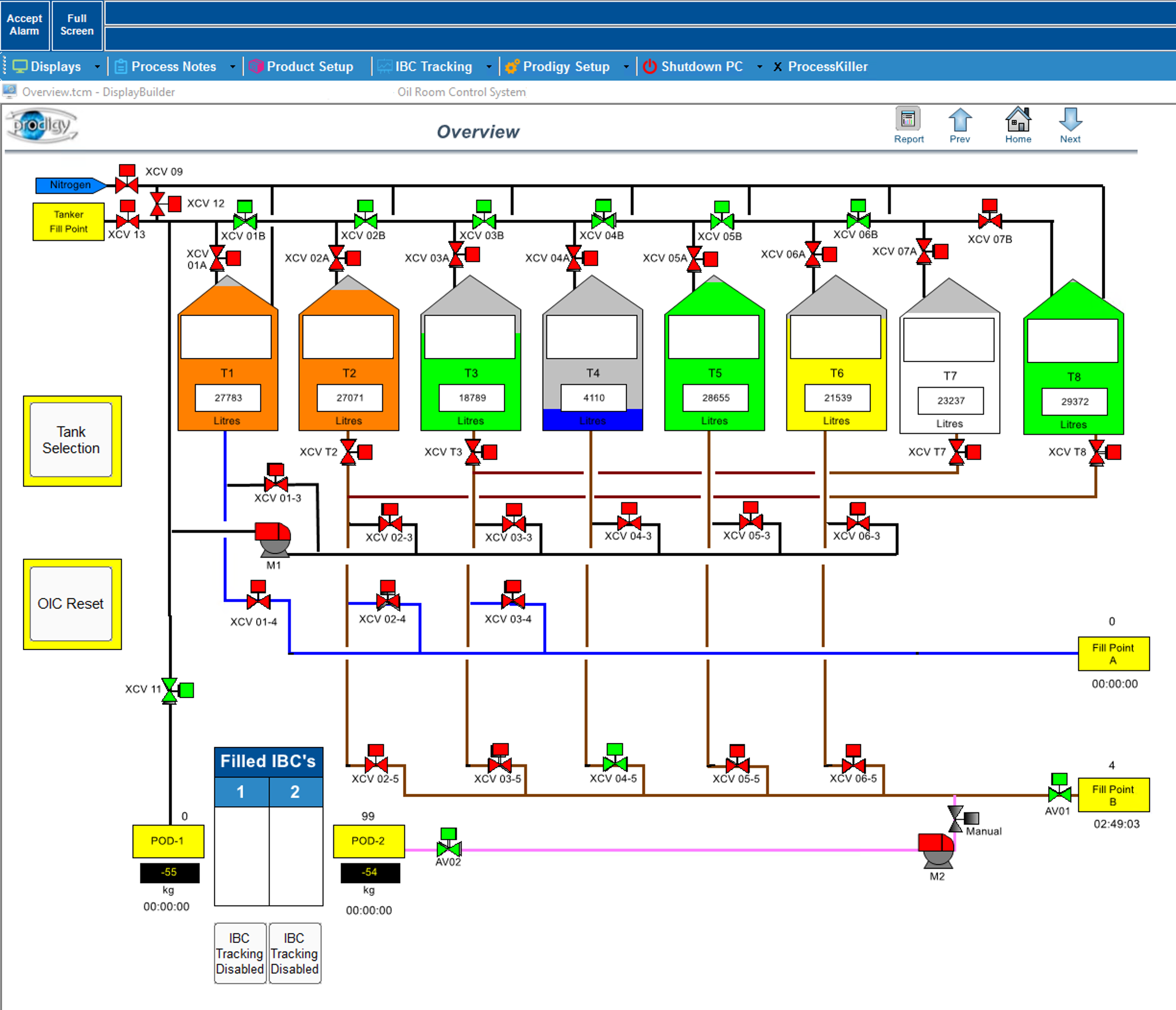

This case study details how Prodigy can track and monitor IBCs of a large oil supplier within the UK.

An oil provider for a range of fast-food shops and restaurants recently upgraded their current Prodigy system, increasing their process visibility and aims to reduce costs. This case study details how Prodigy SCADA has improved the control and monitoring of IBC (intermediate bulk container) tanks.

Why Prodigy SCADA?

When filling a large tank full of oil that is used in the food industry, making sure tanks are filled to the correct volume and cleaned in an orderly process is crucial. Using Prodigy SCADA, tanks can automatically be filled to their defined limits allowing for the process to become automated and readings of volumes will become more consistent.

Also, the system can track the IBC tanks throughout the journey to and from each customer being able to see where damages occur through remote viewing, and to make sure the tanks are returned. Ensuring tanks are returned can reduce unneeded expenses on IBCs when they are not returned, along with identifying who is not returning the IBC tanks.

Tracking the Tanks

With no manual process in the filling and automation in place and the accuracy of the fills are guaranteed, attention can be fully shifted onto the tracking of the tanks.

A barcode system is used to track the cleaning, delivery and in-use stages of the IBCs. This allows operators to locate where the damages are taking place and what preventative measures can be put in motion.

Data On the Server

Each tank has a tag that is scanned in every time a tank reaches a station. With the tanks being scanned, their location is updated into the Prodigy server showing their most recent location.

As a result of the tank tracking and data being uploaded to the server, any IBC damages can be associated to the company in control of the tank, which will hold the company accountable of the damage and be forced to pay a fee.

Key Benefits of Using Prodigy

- Realtime tracking capabilities

- More accurate liquid filling

- Automatic batch / shift report generation

- Compliance with Industry Standards

- Less waste due to damage

- Full visibility of the production and delivery process