Batch and Recipe Handling

Recipe and batch capability are standard requirements in many industries and applications. Prodigy includes comprehensive support for batch and recipe handling.

This includes recipe storage; automatic form filling; automatic batch creation & monitoring and proof of process reporting.

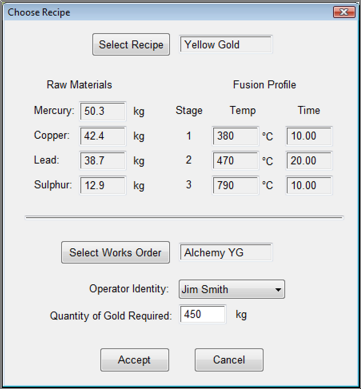

Recipe data is a collection of control setpoints that define the parameters required to make a specific product or to control a specific process. Prodigy allows any number of such recipes to be created and called up via user defined forms.

These forms may display the recipe data and optionally allow items to be modified. They may also allow additional data to be entered that does not form part of the recipe but which may be required as part of the batch history.

Data entered via a form such as the example above may be written to any or all of the following:

- Recipe Database, for the selected recipe

- Batch Database, for the selected batch

- Signal Database, to be used as setpoints etc.

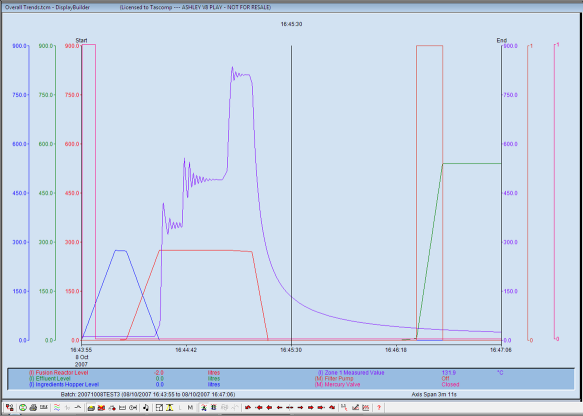

Batch Based Trending

All relevant parts of Prodigy are "batch aware". For instance, batches can be accessed from within historical trends where the start and end dates shown on the trend will be taken from the batch that has been selected.

Prodigy's tag substitution facility means that the same trend can be used to show data from different batches, even if those batches relate to different parts of the plant. For example, if you have 20 different production lines you can configure one trend to look at the data from any one of these lines, rather than having to configure up 20 different trends. This facility also applies to trends shown in the single page proof of process reports.

Batch Data Recorder

Prodigy's Batch Data Recorder makes it easy to handle the requirements of a batch process without the need to write programs or configuration scripts.

Batch Data Recorder works by monitoring the system and watching for the occurrence of any of the criteria that have been defined as meaning that a batch is beginning. This may be something simple such as a digital signal going high or a complex set of conditions that must be met before the batch can commence.

When the batch begins, Batch Data Recorder can reset selected signals and also store the values of any number of signals in to the batch database.

As the batch progresses, the values of any number of signals may be periodically written into the database, to keep a working record of how the batch is progressing.

A batch ends when the conditions defining the end of the batch become true, such as a digital going low, or a given expression evaluating to true. Again, data may be written to the database and signal values reset when the batch ends. Prodigy can also perform statistical surveys, calculating such as mean, max, min, standard deviation, runtime, number of operations etc.

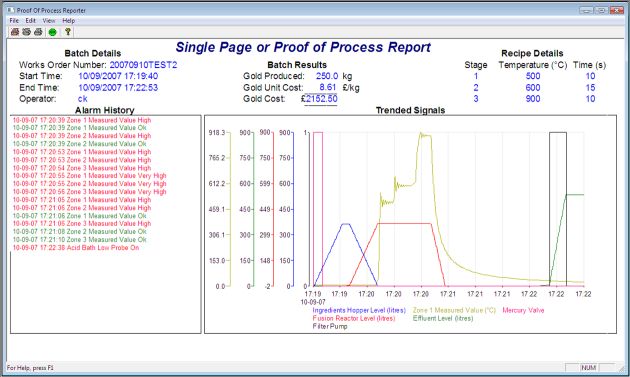

Batch Reporting

Proof of process reports may be generated automatically by Batch Data Recorder when a batch ends. They may also be called up manually at any time. These reports, which are user configurable, can display:

- One off batch data such as Operator ID, batch run time, materials used, total product made etc.

- A list of all the alarms that occurred during the batch.

- Any number of trends each showing any number of signals.

If there is too much data to display neatly on one batch report, Batch Data Recorder can be configured to run as many different reports as required when a batch ends, so you can divide your reports into appropriate subsections of the batch process.